PRODUCTS

A national high-tech enterprise integrating R&D, manufacturing, sales and service

Your location:English → PRODUCTS → Swiss-type lathe → F series Swiss-type lathe → 326F/386F Dual spindle Swiss-type lathe →

PRODUCTS

PRODUCT

CONTACT US

Shenzhen Sowin Precision Machine Tool Co., Ltd

Add.: Area A, Tantou Western Industrial Zone, Songgang Street, Bao'an, Shenzhen, Guangdong, China

M:+86-18128819157

Tel: +86-4000-966-808

E:sales@sowincnc.com

Add.: Area A, Tantou Western Industrial Zone, Songgang Street, Bao'an, Shenzhen, Guangdong, China

M:+86-18128819157

Tel: +86-4000-966-808

E:sales@sowincnc.com

Dual spindle Swiss-type lathe SZ-386F

Model:SZ-386F

Features

●The new one-piece bed, optimized by finite element analysis (FEA), can absorb vibration and reduce resonance while satisfying high rigidity and precision machining

●Standard tol: 35 pcs, (40 can be extended), with rich cutting tools, suitable for the processing of complex parts;

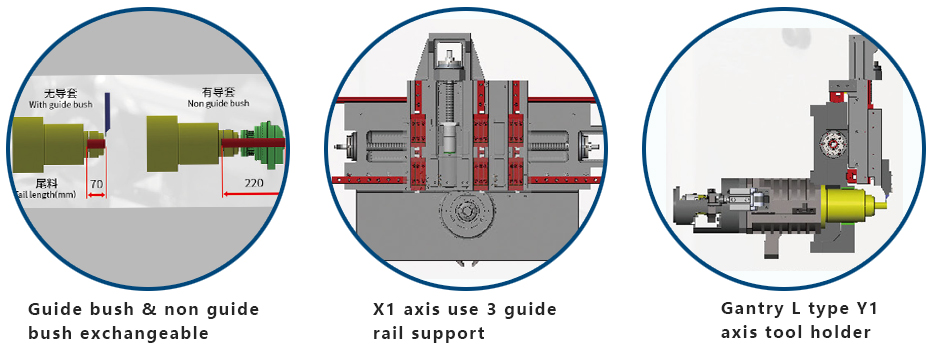

●Mechanical guide sleeve realize high-speed and high-precision machining;

●Cross live tool adopts medium inertia servo motor, large torque tool adopts oil cooling mode, improve the life of power head;

●The sub spindle tool has: turning, side milling, front eccentric processing, boring processing, fully realize the main spindle and sub spindle processing capacity at the same time, efficient production;

Product Details

Processing application:

Medical equipment, hardware tools, textile machinery, electronic communication, aerospace, etc.

| Model | SZ-326F 6 axis, dual spindle | SZ-386F 6 axis, dual spindle | |||

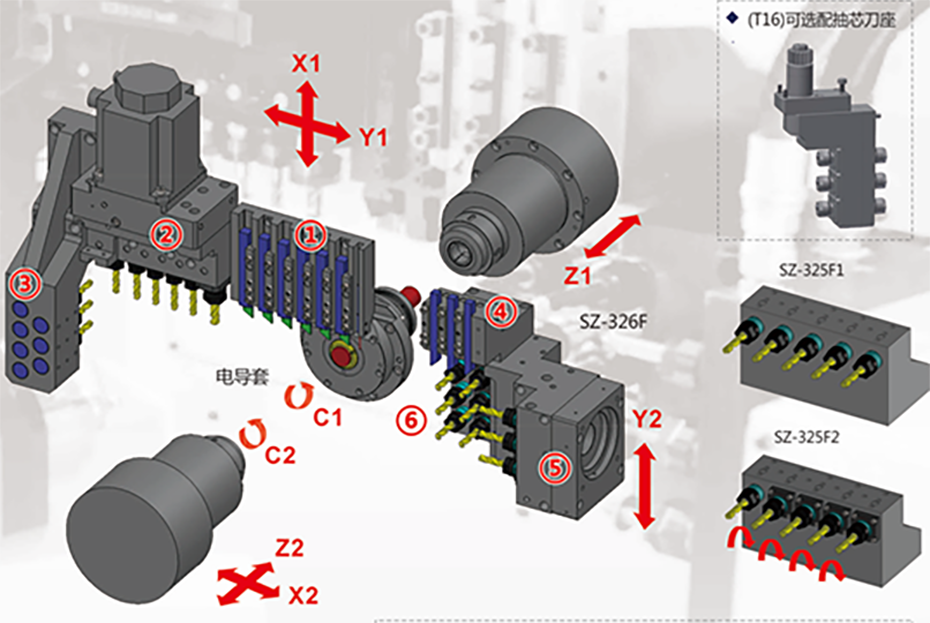

Cutting-tool layout sketch |  |  | |||

| NC device | Mitsubbishi M80 | Mitsubbishi M80 | |||

| Power source | 200AVC | 200AVC | |||

| Lathe rated power | Kw | 20 | 20 | ||

| Machining range | Machining range dia. | mm | ∅ 32 | ∅ 38 | |

Main spindle max clamping dia. | mm | ∅ 32 | ∅ 38 | ||

Max feed length (once) | mm | 320 | 320 | ||

| Main/sub spindle | Main spindle power | Kw | 5.5/7.5 | 5.5/7.5 | |

| Sub spindle power | Kw | 3.7/5.5 | 3.7/5.5 | ||

| Main spindle max through hole dia. | mm | ∅ 39 | ∅ 39 | ||

| C axis resolution | ° | 0.001 | 0.001 | ||

| Main/sub spindle rev speed | rpm | 6000 | 5000 | ||

| Sub spindle max clamping dia. | mm | ∅ 32 | ∅ 38 | ||

| Sub spindle max through hole dia. | mm | ∅ 39 | ∅ 39 | ||

| Main spindle max drilling depth | mm | 60 | 60 | ||

| Main spindle max travel | With guide bush | mm | 320 | 320 | |

| Non guide bush | mm | 80 | 80 | ||

| Max tool installed qty. | pcs | 35 | 35 | ||

| Main spindle tool | |||||

| ①OD Turning tool | Qty.×Model | 6X¨16 | 4X□16+1X□20 | ||

| ②Cross live tool | Qty.×Model | 5XER16+1XER20 | 5XER16+1XER20 | ||

| Drilling dia. | mm | ∅ 10 | ∅ 10 | ||

| Tapping/Threading die dia. | M8 | M8 | |||

| Live tool rev speed | rpm | Max 4500 | Max 4500 | ||

| Live tool power | Kw | 1.5 | 1.5 | ||

| ③End face fixed tool | Qty.×Model | 7XER16 | 7XER16 | ||

| Drilling dia. | mm | ∅ 10 | ∅ 10 | ||

| Tapping/Threading die dia. | M8 | M8 | |||

| Sub spindle tool | |||||

| ⑥End face fixed | Qty.×Model | 4×ER16 | 4×ER16 | ||

| Drilling dia. | mm | Max φ10 | Max φ10 | ||

Tapping/Threading die dia. | Max M8 | Max M8 | |||

| Live tool | ⑥End face live tool | Qty.×Model | 4×ER16 | 4×ER16 | |

| Drilling dia. | mm | Max φ10 | Max φ10 | ||

| Tapping/Threading die dia. | Max M8 | Max M8 | |||

Live tool rev speed | rpm | Max 4500 | Max 4500 | ||

| Live tool power | Kw | 1.5 | 1.5 | ||

| ⑤Cross live tool | Qty.×Model | 4×ER16 | 4×ER16 | ||

| Drilling dia. | mm | Max φ10 | Max φ10 | ||

| Tapping/Threading die dia. | Max M8 | Max M8 | |||

| ④OD Turning tool | 4X¨12 | 4X¨12 | |||

| Electronic rotary guide bush | Kw | 1 | 1 | ||

| Rapid feed speed | m/min | 24(Z1/Z2/X1/X2/Y1/Y2) | 24(Z1/Z2/X1/X2/Y1/Y2) | ||

| Feed motor power | Kw | 1.5(Z1/Z2/X1/X2/Y1/Y2) | 1.5(Z1/Z2/X1/X2/Y1/Y2) | ||

| Cutting oil pump power | Kw | 0.4 | 0.4 | ||

| Main/sub spindle cooling oil pump power | Kw | 1.2 | 1.2 | ||

| Lubricating oil pump power | Kw | 0.015 | 0.015 | ||

| Max collecting length of workpieces collect box | mm | 100 | 100 | ||

Main/sub spindle center to the bottom of lathe body | mm | 1100 | 1100 | ||

| Cutting oil tank volume | L | 180 | 180 | ||

| Air pressure | Mpa | ≥0.5 | ≥0.5 | ||

| Net weight | Kg | 5000 | 5000 | ||

| Dimensions(L×W×H) | mm | 2850X1600X2060 | 2850X1600X2060 | ||

Notes:Technical parameters are subject to change without prior notice.

| 326F/386F series | ||

| OP system | SYNTEC 220TB | FANUC Oi-TF Plus |

| Power source | 380VAC | 200VAC |

| Cross live tool power | 1.7Kw | 1.2Kw |

| Cross live tool rev speed | 4500rpm | 4500rpm |

| Back live tool power | 1.7Kw | 1.2Kw |

| Back live tool rev speed | 4500rpm | 4500rpm |

| Feed motor power | 1.7Kw(Z1/Z2/X1/X2/Y1/Y2) | 1.2Kw(Z1/Z2/X1/X2/Y1/Y2) |

| Rapid feed speed | 24(Z1/Z2/X1/X2/Y1/Y2) | 24(Z1/Z2/X1/X2/Y1/Y2) |

Standard configuration

1. Taiwan syntec control system

Japan FANUC control system

2. 10.4 inch Color LCD display

3. Main/sub spindle cooling system

4. Lricating system

5. Rotatory guide bush

6. Main/sub spindle air blowing device

7. Main/sub spindle air blowing device

8. Electric leakage protection

9. Transformer

10. External light connector

11. 3-colour tower light

12. HIWIN/PMI screw/guide rail, Class 3

13. Cutting oil tank

14. Main/sub spindle collet 1pcs; guide bush 1 pcs

15. Tool cabinet

16. Chip conveyor

17. Manual book

Installation size:

1. Taiwan syntec control system

Japan FANUC control system

2. 10.4 inch Color LCD display

3. Main/sub spindle cooling system

4. Lricating system

5. Rotatory guide bush

6. Main/sub spindle air blowing device

7. Main/sub spindle air blowing device

8. Electric leakage protection

9. Transformer

10. External light connector

11. 3-colour tower light

12. HIWIN/PMI screw/guide rail, Class 3

13. Cutting oil tank

14. Main/sub spindle collet 1pcs; guide bush 1 pcs

15. Tool cabinet

16. Chip conveyor

17. Manual book

Installation size:

Optional configuration

1. Automatic bar feeder

2. Chip conveyor

3. Oil mist collector

4. High pressure pump

5. Long workpiece collector

6. Workpiece belt conveyor

7. xternal working litht

8. Electric leakage protection

9. cut-off tool breakage detector

10. Special shaped material clamping device

11.Thread whirling tool holder

12. Front eccentric tool holder

1. Automatic bar feeder

2. Chip conveyor

3. Oil mist collector

4. High pressure pump

5. Long workpiece collector

6. Workpiece belt conveyor

7. xternal working litht

8. Electric leakage protection

9. cut-off tool breakage detector

10. Special shaped material clamping device

11.Thread whirling tool holder

12. Front eccentric tool holder